- Tubindus Zone industrielle Plan d'Acier 39200 Saint-Claude France

- contact@tubindus.com

- +33 3 84 45 36 88

Contact us

- Zone industrielle Plan d'Acier, 39200 Saint-Claude, FRANCE

- contact@tubindus.fr

- +33 3 84 45 36 88

Industrial subcontracting

Tube specialist for 80 years

Tubindus specializes in the manufacture of steel, stainless steel and aluminum tube parts in all cross-sections (round, square, rectangular...).

Our company relies on :

-

cutting-edge R&D designed to meet every requirement,

-

a complete service from design to surface treatment

-

half a century of expertise

We can meet a wide range of requirements:

-

automotive

-

agricultural machinery

-

hospital furniture

-

leisure furniture

-

stadium equipment and stands

-

all other applications

Our expertise

For 3 generations, Tubindus has been in the business of transforming steel, aluminum and stainless steel tubes of all cross-sections (round, square, rectangular...). We put at your disposal the strength and resources of an industrial structure adapted to meet the demands of small and medium-sized production runs.

Our investment policy enables us to constantly evolve towards the technologies needed to process your products.

We have several cutting and brushing machines, some of which are integrated directly into automatic lines.

Tubindus invested several years ago in a laser tube. This high-performance equipment enables us to offer new technical solutions.

In 2014, we invested in a laser sheet metal. This equipment enables us to increase our service and responsiveness to our customers in the case of short production runs.

We have a large number of CNC bending machines. Our current range extends from Ø 5mm to Ø 89mm. We also have a bending machine all-electric and robotic with capacity to produce hangers with variable radius.

Tubindus implements crush-cut technology on a fully-automated cell press.

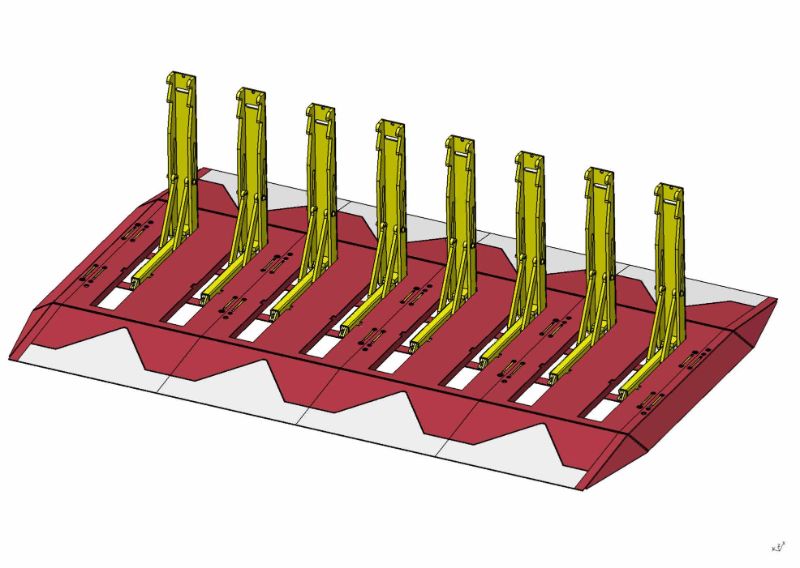

DALITUB has been integrating welding robots into its processes for over 20 years. Today, we are able to weld steel, aluminum and stainless steel thanks to a fleet of 10 welding robots.

For small production runs, we are equipped with manual welding units.

For over 30 years, Tubindus has integrated painting into the manufacturing process.

We can finish your products with an epoxy or polyester paint and a surface treatment that meets the highest standards:

- Degreasing

- Rinse

- Phosphating

- Chromium passivation

- Drying

- Electrostatic powder coating

- Paint polymerization in a baking oven

We also have a industrial paint with surface preparation by metallization (pure zinc or zinc-aluminium). This installation has the capacity to process large-volume parts (6 m * 3 m * 4 m).

Tubindus is equipped to offer assembly services for your products.